Feb

5

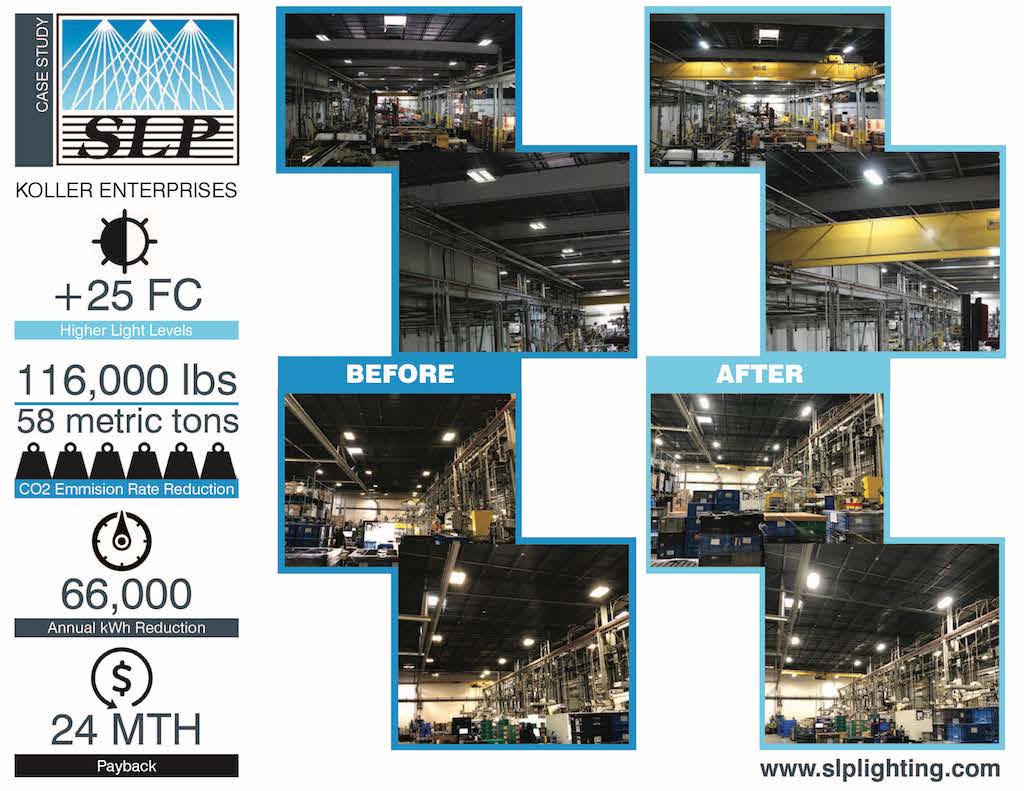

Case Study for Citadel 4 LED

Koller Enterprises is a plastic injection processer that produces large numbers of parts of high quality with great accuracy, very quickly. Plastic material in the form of granules is melted until soft enough to be injected under pressure to fill a mould. The result is that the shape is exactly copied at a rapid pace.

Lighting Challenge:

The current installed lighting system was over 10 years old, the system consisted of 65 — (6) lamp T5HO high-bays. Time and maintenance created a very ineffective lighting due to large presses, overhead cranes, and large steel columns creating shadows. Light levels were low and uneven in areas where inspection was critical. The need for improved lighting was just not a need but requirement. Foot-candle (FC) levels were anywhere from 5 FC to 12 FC plant wide.

Lighting Solution:

Replace the entire space with new Citadel 4 LED fixtures. The small yet simple retrofit achieved amazing results. higher light levels equaling +25 FC average, and a total reduction in energy usage (annualized) 66,000 KWH for a savings of $7,988. CO2 emission rate reduction 116,000 lbs. or 58 metric tons for a Greener Missouri. PAYBACK = 24 months

Additional Benefits:

- Increased light levels

- Increased worker satisfaction and

- productivity

- Instant On/Off

- Improved quality Control

- Maintenance saving (longer LED life)